PARIS — Airbus and Boeing are each helping with tests of a radical new engine design with an open fan being developed by CFM International, making it a prime candidate to power the next generation of all new airplanes in the mid-to-late 2030s.

The new engine with a giant open fan would change the look of airplanes and provide deep cuts to carbon emissions for the next generation of new jets.

Boeing CEO Dave Calhoun said this month that “you can’t deny both the emission and efficiency gains you get from it.”

In Paris on Friday, Airbus Chief Technology Officer Sabine Klauke said the European manufacturer plans to test fly the open fan aspect of the CFM concept on one of its A380 superjumbo jets around mid-decade.

Around that time, Boeing will test fly another aspect of the CFM design — a hybrid electric capability to save fuel — on a Saab 340 turboprop.

GE and French engine maker Safran, who together form the 50:50 CFM joint venture, are already building and testing hardware components.

“It’s not on paper anymore. It’s for real,” Mohamed Ali, vice president of engineering for GE Aerospace, said in Paris.

In a briefing Monday at the GE chalet at the Paris Air Show, Ali made an impassioned pitch for his team’s new design.

“It’s our belief that the today’s architecture for engines is on diminishing returns in terms of the ability to achieve significant improvements in fuel burn capability,” he said.

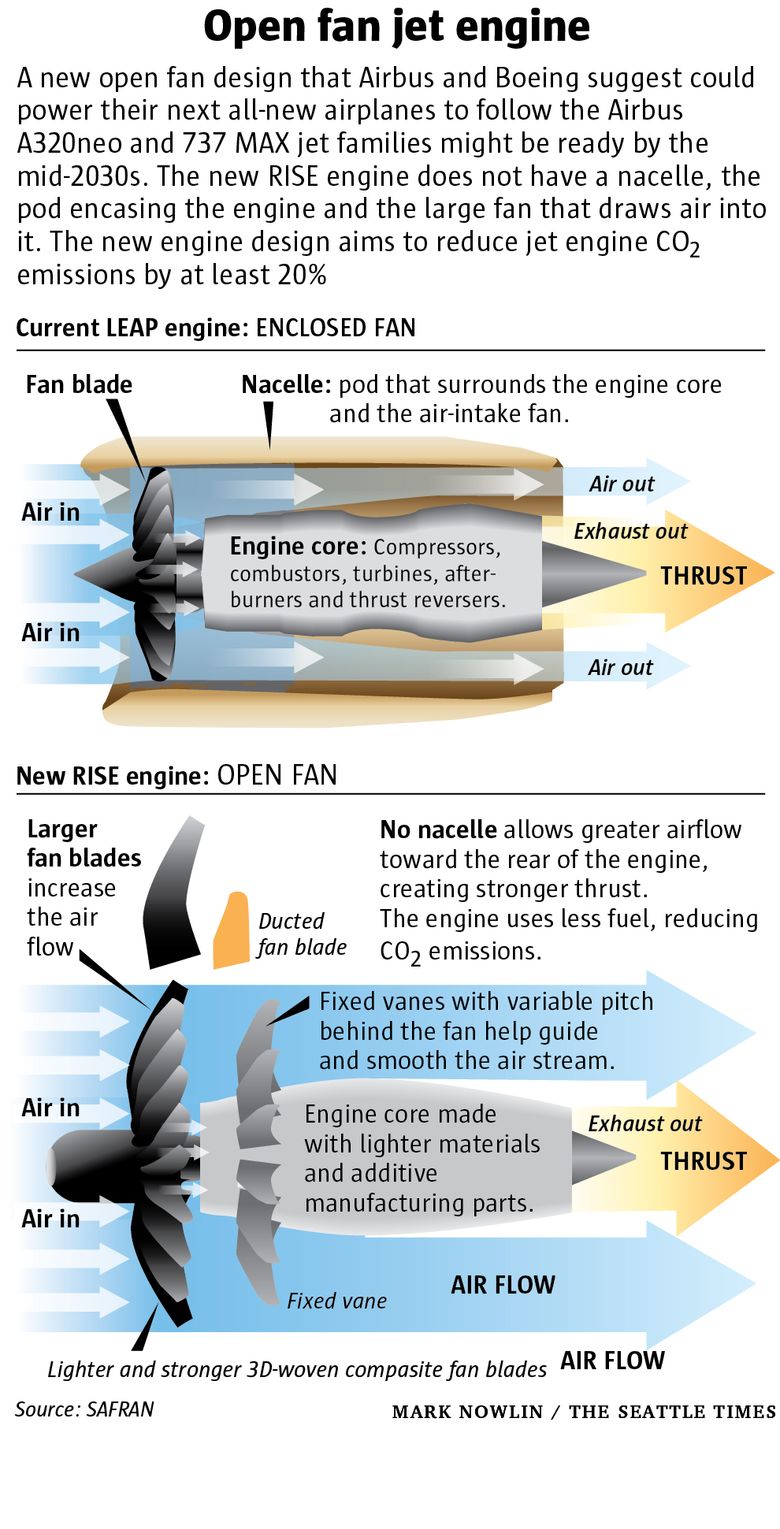

But Ali said removing the pod, known as a nacelle, that on today’s jets encases the engine, allows a much bigger fan at the front to generate much more thrust and substantially better fuel efficiency that “cannot be achieved any other way.”

“It’s not fair quite honestly for the planet or for the environment or for the industry to leave that on the table,” Ali concluded.

Blades that change pitch, vanes that close

CFM has dubbed its new engine design project Revolutionary Innovation for Sustainable Engines, or RISE.

The open fan at the front is only the most visible of a suite of revolutionary changes it is researching for the engine.

On a half-size scale model on display at the GE chalet, the fan is certainly impressive.

This engine is designed for a single-aisle-sized airplane like the 737 MAX, but the fan blades on it will be about as long as those on the GE-9X engine that will power Boeing’s giant 777X widebody jet.

That implies a diameter of around 11 feet, almost twice the diameter of the LEAP engine on the 737 MAX.

The blades can move to change their pitch and adjust the air flow, as can a set of fixed vanes just behind the fan. Those vanes are designed to guide and smooth the air flow to avoid it swirling away from the engine.

In today’s engines, when the pilot brakes on landing a complex mechanism called a thrust reverser inside the engine deploys to block the backward air flow and slow the plane down.

In the RISE, there’s no thrust reverser. The fixed vanes behind the fan can change pitch so that they almost close together, blocking the air stream and serving as that brake.

Christopher Lorence, chief engineer at GE Aerospace said doing away with the heavy nacelle pod and the internal thrust reverser saves about a ton of weight on each engine.

A suite of design changes, not just a big fan

Besides the giant fan, another striking aspect of the RISE concept is the tiny engine core. That’s the part of the engine where the air is sucked in, compressed, ignited and blown out the back.

The size of the core in the RISE is similar to that of a small business jet engine.

Ali said GE and Safran used an advanced supercomputer to design every aspect of the jet including the advanced materials and additive manufacturing processes used to make intricate inner nozzles and cooling paths within the core.

“We are the only nongovernment entity that’s using that, the most powerful supercomputer in the world,” he said. “We used that to design the fan. We are also using it to design many aspects of the core.”

And CFM is also trying to make the engine hybrid-electric.

On today’s airplanes like the 787 Dreamliner, the fan that spins the central shaft generates electricity used to power various systems on the aircraft. On the RISE, that electricity will also be used at times to help turn the shaft.

When a hybrid electric car is running on electricity, it’s not using gas. For a plane, that’s a new concept for added fuel efficiency.

Both Airbus and Boeing seemed convinced of the promise of the engine. Each aspect and every component must now be tested ahead of flying a complete engine suite in 2028 to prove the concept will deliver on that promise.

If it does, Airbus and Boeing may face a decision between two very different engine types when they come to build their next all new plane.

Will they choose this revolutionary RISE? Or will they go with Pratt & Whitney’s more conventional architecture, with likely a lesser improvement in fuel burn?

If Boeing chooses the former, they’ll have to redesign the airframe significantly to accommodate the giant fan.

Boeing Commercial Airplanes CEO Stan Deal in Paris said Boeing will keep an open mind and that the more conventional engine is “probably a lower technical risk, relative to RISE.”

“I will tell you, GE has technologically superior engines, we’ve seen that over history,” Deal added.

GE’s Ali believes the pressure on aviation to address climate change and lower emissions more dramatically means it’s time for a revolution.