The Sound Insulation Repair and Replacement Pilot Program was granted approval by the Port of Seattle Commission on February 27, 2024.

This pilot program is to help assess products that were previously installed as part of the Sound Insulation Program and evaluate the current condition of those installations. The assessment was completed in December 2024. This assessment included extensive outreach, collection of information from property owners within the study area, research on the expected useful life of building materials and acoustic testing. The assessment report was provided to the Commission in January 2025.

The eligibility criteria for a sound insulation repair and replacement pilot program have yet to be determined by Commission. Once determined, additional information will be provided.

View local area aircraft flight tracks and noise

Sound Insulation Repair and Replacement Pilot Program: Assessment Technical Report

The Port of Seattle has heard concerns from community members about the condition of sound insulation treatments installed several decades ago. On February 27, 2024, the Port of Seattle Commission issued Order 2024-04 to study these concerns. The survey was conducted from June 3, 2024 to August 9, 2024. Responses to the survey will not be used for any other Port of Seattle programs or studies and are subject to Public Disclosure. It is also important to know that participation in the survey did not guarantee repair, replacement, or maintenance outcomes for any residence.

The information gained through the survey, acoustic testing, field assessment and additional research on the expected useful life of products was critical in gaining a better understanding of the issue at hand. The details of the assessment and findings are captured in the Technical Report, link below. A summary of the findings include:

- Survey results and field inspections provided good information on understanding resident concerns about window glass appearance and operation (ease of opening/closing and locking).

- The responses received reflected the geographic distribution of original installations.

- The responses received reflected the various window manufacturers used across time.

- There were no significant trends in the survey results that distinguish one particular manufacturer or year of installation as a problem.

- Overall age of sound insulation packages and individual issues with window design, installation and/or maintenance were identified as probable causes of appearance and operational problems.

- Ninety-nine percent (99%) of the windows installed prior to 2014 are past the industry-standard expected useful life.

- None of the 30 residences acoustically tested exceeded the FAA-established interior noise threshold of 45db DNL for residential use compatibility and for sound insulation program eligibility, indicating all acoustically tested windows and doors were continuing to provide appropriate sound insulation.

The results of the assessment provide valuable information for the Port’s understanding of the scope and scale of the issue and developing a sound insulation repair and replacement pilot program. The assessment would not have been possible without the strong community response in taking the SEA Sound Insulation Repair and Replacement Pilot Program survey and the 30 sets of residents who participated in the field inspection and acoustic testing phase with the use of their homes. With the assessment findings now completed, the Port is currently developing the framework and details for the Pilot Program.

Sound Insulation Pilot Program Repair and Replacement Technical Assessment Report (24 KB)

Sound Insulation Pilot Program Repair and Replacement Technical Report Appendix A – Survey Materials (3 KB)

Sound Insulation Pilot Program Technical Report Appendix B – Survey Results (800 KB)

Sound Insulation Pilot Program Technical Report Appendix C – life Expectancy of Building Materials (1,800 KB)

Sound Insulation Pilot Program Technical Report Appendix D Sound Insulation Testing Materials (10,000 KB)

Replacement Options

The following material is provided for informational purposes only and should not be considered an endorsement by the Port of Seattle. We recognize that some homeowners may wish to replace windows for other reasons or on a faster timeline than the Port can deliver. You can use this page as a resource when searching for windows that provide equivalent soundproofing to those previously installed by the Port.

The Port of Seattle has installed sound insulation packages in nearly 10,000 homes over the past 40 years. A variety of products by different manufactures were installed at different time periods. Certain products may still be under manufacturer’s warranty. Explore the Milgard Windows Replacement Options in the pull-down tabs of this webpage to see if you have Milgard Windows.

Window Sound Control – Explaining ratings

A window’s acoustic performance or ability to reduce exterior noise is measured by either a Sound Transmission Class (STC) rating or an Outdoor-Indoor Transmission Class (OITC) rating. Both provide a single number rating. The higher the rating, the greater levels of sound reduction.

The Federal Aviation Administration (FAA) requires Sound Insulation Programs use window products with a STC rating of 44 or OITC of 32. Window products that meet the STC44 or OITC32 ratings are not readily available in the market.

Acoustic-rated windows

Below are the currently known manufacturers of these products that are used by SEA and other FAA Sound Insulation Programs. Not all manufacturers will sell to the public and may have minimum quantity requirements that are greater than a single home. Contact the manufacturer for more information:

| WINDOW SYSTEMS: | |

|---|---|

| Stergis Windows | Sonic Sound Reduction Windows Reduce Noise Pollution |

| Prime Windows | Silent Guard® Acoustic Window Series | Prime Window Systems |

| AMSCO Windows | Serenity Series – AMSCO Windows |

| Mon-Ray Windows | MON-RAY, INC. | High Performance Windows and Doors |

| St. Cloud Windows | Custom Commercial Window & Door Manufacturer |

Other window options and Storm windows

If purchasing STC44 or OITC32 products is impractical, explore using windows that are not part of the FAA sound insulation program. They will have ratings ranging from 26 to 37 STC. Pairing the highest available STC/OITC rating window you can purchase with a storm window may be a good alternative. A storm window is a secondary window that can be installed on the outside or inside of the home as shown here. The US Department of Energy explains the benefits, such as reducing noise and improving energy efficiency associated with installing storm windows: Storm Windows | Department of Energy

Below are the currently known manufacturers of operable and fixed storm windows. Contact the manufacturer for more information:

| STORM ADD ON | |

|---|---|

| Mon-Ray Windows | MON-RAY, INC. | High Performance Windows and Doors |

| Soundproof Windows | Soundproof Windows, Inc. | Eliminate Your Noise Problem |

| Indow (not operable) | Reduce Noise with Window Inserts | Indow Window Inserts |

Glass replacement vs window replacement

In some cases, replacing the glass instead of the entire window may be a good option. Finding a local window dealer that also provides glass replacement is a good first step. If you need parts or glass replacement, they may be able to perform that work for you at a reasonable cost. They would also assist you in determining if a replacement window is needed.

Examples of common glass conditions Condensation, Seal Failure and Low E coating defect are explained in the other pull-down tabs of this webpage.

Disclaimer

The above is provided for informational purposes only. The Port of Seattle does not recommend or provide warranties for products. There is no funding available to reimburse replacement of windows outside of the Port’s pilot program. Replacing windows outside of an FAA-approved program could affect eligibility for the Port’s pilot program.

Milgard Windows – Replacement Options

The Port of Seattle has installed sound insulation packages in nearly 10,000 homes over the past 40 years. A variety of products by different manufacturers were installed at different time periods. Certain products may still be under manufacturer’s warranty.

If your home has Milgard products, they may still be under the warranty provided by Milgard Windows. For warranty or replacement parts, please contact Milgard at Find Your Warranty | MILGARD

You can identify Milgard Windows by looking at your locking hardware to see if it has the Milgard logo or by a sticker on the window frame under MFR Code.

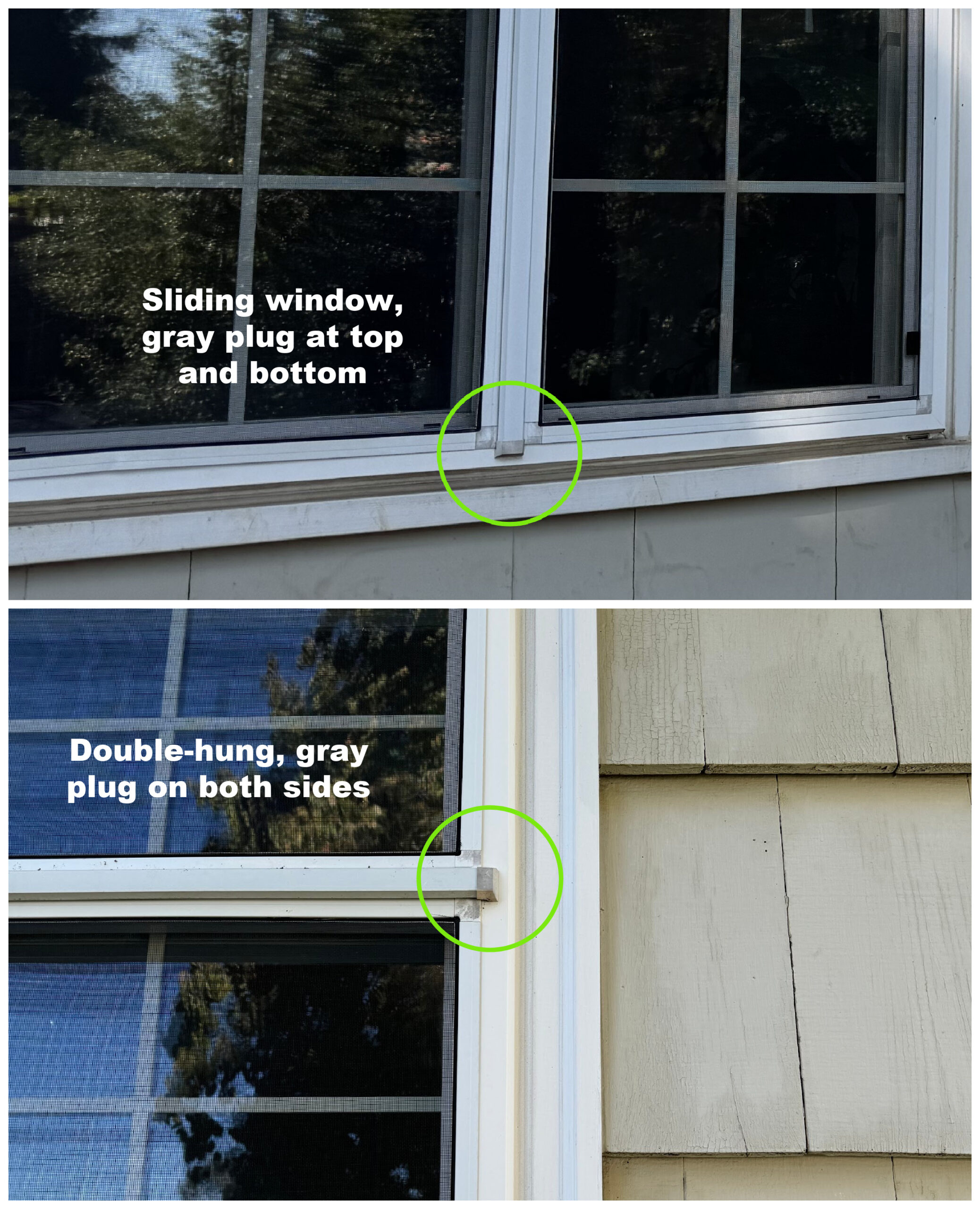

Milgard Windows QuietLine products were used by several Sound Insulation Programs in the 2000’s and have a distinct exterior profile that has a thick rail between the two sashes with a grey colored end plug:

If you have Milgard Windows, the manufacturer can be a valuable resource regardless of warranty status. For warranty or replacement parts, please contact Milgard at Find Your Warranty | MILGARD

Condensation

What Is Condensation?

Is your glass “sweating” – is water beading or ice forming on the inside surface of your windows? There’s a good chance that what you are seeing is condensation, a sign that there is excess humidity in your home. Humidity – water vapor mixed with air – is drawn to the coolest surfaces, such as your window. Cool air cannot hold as much moisture as warm air, so windows and doors often collect this moisture and make it visible. A surface that is cooler than room temperature is more likely to show condensation. Condensation is not a product defect. If you have excess condensation, please explore ways to limit humidity and regularly clean surfaces.

What Causes Condensation?

Indoor moisture is caused by a variety of factors, including cooking, showering, running dishwashers, storing firewood, pets, fish tanks, plants, clothes dryers that are not vented properly, even breathing. Your new windows are most likely showing condensation more than your old ones because they are more airtight – less air is entering your home from the outside. The air leaking from older windows evaporated the moisture before it could collect.

Why is condensation forming at the bottom of the window?

Each insulated unit is a sealed atmosphere, and the air in this atmosphere becomes layered, just as in any closed space. Warm air rises, and since humidity is attracted to cooler air, condensation will often show near the bottom of the glass.

Window Glass Seal Failure

Your windows have an insulated glass unit (IG) that consists of two panes of glass with a metal spacer in between them that are adhesively sealed to the spacer. If the adhesive seal breaks or releases, air and moisture can enter the space between the 2 panes of glass. When this happens, you might start to notice fogging, moisture and streaking between the panes of glass.

This defect is called a Seal Failure. Because this condition is in between the panes of glass, you are not able to wipe them away.

Low Emissivity (LoE) Window Coating Defect

Your windows have an insulated glass unit (IG) that consists of two panes of glass with a metal spacer in between them that are adhesively sealed to the spacer. On the inner surface of the glass, a LoE coating is applied. A LoE coating is a microscopic, metallic oxide that is nearly invisible coating that help to improve the energy efficiency of windows by blocking part of the sun’s heat in summer and reduces heat from escaping in winter.

If the LoE coating fails, you will start to see small spots appear in between the 2 panes of glass. Because this condition is in between the panes of glass, you are not able to wipe them away. Over time, the spots will grow as more of the microscopic, metallic oxide fails; the small spots will become larger areas over time.